When doing a safety audit in the workplace, utilizing an electrical inspection checklist is essential to capturing all points of investigative interest during your inspection. However, finding a comprehensive yet manageable electrical inspection checklist to help meet a final project compliance audit can be challenging and even downright frustrating. So, we felt it was time for someone to produce a manageable document, both in downloadable PDF and digital format, for your auditing and inspection needs – enter the downloadable Electrical Inspection Checklist .

The Electrical Inspection Checklist uses standard electrical hazard identification in a compact and manageable format. Your business can use this PDF form or our app, 1st Reporting , to complete job site facility electrical inspections and audits inefficiently and effectively in preparation for a project completion inspection by a government-appointed official.

Keep reading to discover all the details of the free downloadable electrical inspection checklist template. We’ll cover what’s included on the checklist template, how we recommend you use the template to further your business facility’s electrical safety, and some tips and other solutions for you to utilize this downloadable electrical inspection checklist and more to your best advantage.

Table of Contents

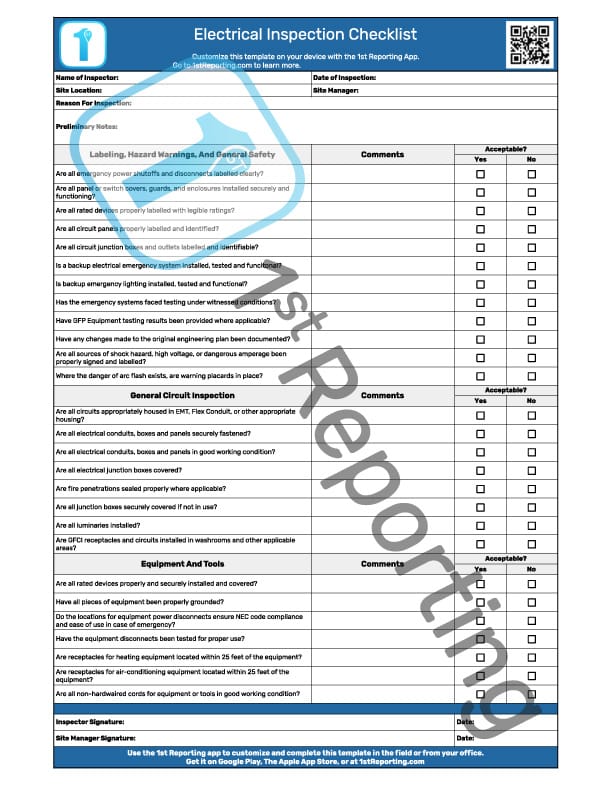

The fundamentals of a completed electrical project inspection are included in the three main sections of the Electrical Inspection Checklist. These sections are:

Each section encompasses a general area of electrical inspection relating to the final electrical inspection necessary in most jurisdictions following a permitted construction or renovation involving electrical work.

Labeling circuits, panels, motors, equipment, and even receptacles and switches is an excellent idea for any business. Having a site plan, including an electrical layout, is smart when a company intends to function in case of electricity failure. Even a simple office needs power and knows where to turn a breaker back on when overloading a circuit.

General circuit inspections include checking the physical installation of the system’s conduits, boxes, panels, and components. Including items such as fire penetration sealing is vital for those installations where specific guidelines are required.

Depending on location conditions, most jurisdictions have strict regulations regarding GFCI circuits. As almost every facility includes a bathroom (one typical place where we see GFCI circuits regularly), we’ve included the item as a checkpoint in your general circuit inspection. After all, having the correct equipment for the job is essential for passing your final inspection.

Facilities that undergo construction, renovations, or other jobs that require the change or addition of electrical circuits often do so out of equipment or process necessity. For example, a coffee manufacturer might add a second kettle to their process, requiring a new circuit from the panel to the manufacturing floor, where the kettle finds its permanent location on the line.

Equipment in manufacturing and other facilities often has higher than standard requirements for electrical use.

In countries like Canada, equipment requiring a 240-volt circuit is expected to be found. Some even require a 3-phase circuit. The amperage requirements might be a 20- or even 30-amp service.

Meanwhile, in the United States, another commonly found voltage for machinery is 460 volts. Again, a 3-phase power source is not unheard of either. Nor is a 600-volt feed for a motor or other electrical device used at your facility.

A typical example of these sorts of higher voltage, amperage, phase, or all of the above are found at most buildings’ shipping and receiving bays. The loading docks and door operators often run at higher voltage and amperage circuits to accommodate the equipment-specific power requirements. Many businesses face a common situation when wiring up new or replacement equipment – and inspections are usually required. Doing things to code and ensuring things are installed by a professional is essential.

Using the equipment and tools section of the electrical inspection checklist, complete the items and add comments as required to ensure that any follow-up work is clearly understood and completed.

Handy Resources: Want to see what’s required by law for your electrical safety standards?

The best situation for using our downloadable Electrical Inspection Checklist is before a final inspection by a government-approved electrical inspector. These scenarios may include:

The Electrical Inspection Checklist is relatively straightforward. You need to download the checklist, print it, and provide a copy or two to your in-house inspection team.

When your company does an electrical renovation, repair, or installation requiring an official audit, such as an inspector from the local building code office, you must ensure you pass – the first time. To aid you in this endeavor, we’ve got three tips to help you achieve this goal.

Whether you are operating a construction company, a boutique store, a property management firm, or even a utility department, you must understand the value of safety. Concluding that safety is vital, it is apparent that invisible dangers such as electricity are real threats to the stability of the safety we do our best to instill in the workplace.

However, including a robust electrical safety policy in your daily operations is something that you should complete out of a desire to improve safety and company culture. It should not be fueled by fear, whether real or perceived.

Aside from the obvious potential to save life and limb, there are several benefits to a robust electrical safety policy in your business.

We mentioned how using something like a mobile reporting app like 1st Incident Reporting to complete your electrical and other safety inspections on the go digitally was an intelligent move. But we didn’t understand how automating processes using a digital and mobile reporting app can decrease labor costs.

Consider the cost of administration, filing, delivering paperwork, and so forth. Now, consider the waste that paper creates, the cost of ink, toner, paper, printer rental, and electricity to run the printer. You even need to pay someone to print the checklist. All kinds of small costs are incurred when operating by non-digital means, but labor is typically the most expensive.

At the same time as saving on labor fees, automation for electrical inspections also increases efficiency. Imagine your staff completes an inspection scheduled for a Saturday during a plant shutdown. Being a digital report, you receive a notification (per your custom setup) when your staff completes and submits the checklist. Now you know your staff has completed their task no matter where you are. Again we see the efficiency of automating tasks and the trickle effect of further information available to you at near-instant sharing speed.

Similarly, consider the cost of a person who has to walk a stack of inspection checklists to another office. Are those checklists even clean? In an age of pandemics, the less physical sharing of inspection reports, the better.

Our Electrical Inspection Checklist for you to download today intends to provide a tool and outline for a generally completed project/site electrical inspection. The checklist will aid your compliance with final electrical inspections of construction and other electrical work projects.

As you are likely well aware, there are many specialized electrical audit or inspection types, with an equal number of reasons why an electrical inspection may be required. Similarly, depending on the role of the individual within an organization, an electrical inspection checklist could actually mean one of many different types, so specificity is critical to getting an appropriate checklist for your audit.

Using a customizable digital reporting app, like the one you can download from the Google Play Store or the Apple App Store (1st Reporting app), is the best option for your electrical inspection reporting needs. You can customize all the site-specific questions you need your staff to ask or procedures your staff needs to perform.

Automating and mobilizing your reporting, auditing, and inspection needs is one option to get your company moving with the times. However, there is nothing wrong with downloading the checklist and taking full advantage of its usefulness.

Test the digital reporting experience for yourself, see how your company can automate processes, and instantly share field reports and data, including photos, video, and other media, right into your shared audits and more. Get your trial started today at 1stReporting.com.